est 2002

We Specialize In:

• Custom Manufacturing (Small or Large Production Runs) • Corrosion Resistant Fiberglass Solutions for Industrial and Oilfield Applications • Conceptual Design, Master & Mold Building • Onsite Tank Repairs & Modifications • TDG Tank Manufacturing / Repair / Modifications

Leaders in Custom Fiberglass

Manufacturing & Repair

Transport Canada Registered Facilty

for Fiberglass TDG

Manufacturing /Repair / Modification

est 2002

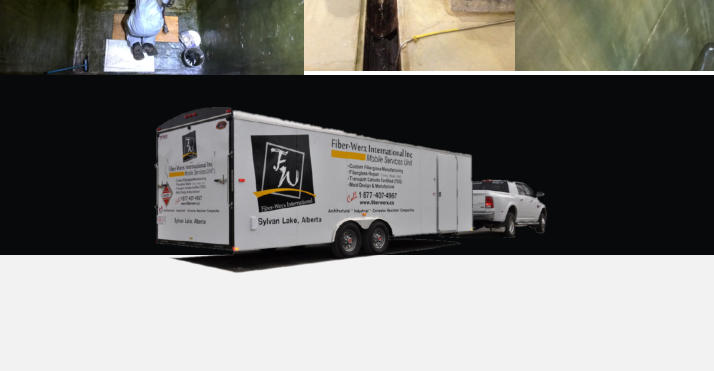

Mobile Repair & Modification Unit

for FRP Tank and Industrial Service

Hours:

Mon - Fri 8:00am - 4:30 pm

Closed Weekends & Holidays

Proven Dual Containment Solutions

for SAGD Sumps and Trenches

Alberta’s Only Transport Canada Registered Facility

For Fiberglass

Manufacturing / Repair & Modification

of TDG Tanks

Leaders in Custom Fiberglass

Manufacturing & Repair

Transport Canada Registered Facilty

for Fiberglass TDG

Manufacturing /Repair / Modification

Mobile Repair & Modification Unit

for FRP Tank and Industrial Service

We Specialize In:

• Custom Manufacturing (Small or Large Production Runs) • Corrosion Resistant Fiberglass Solutions for Industrial and Oilfield Applications • Conceptual Design, Master & Mold Building • Onsite Tank Repairs & Modifications • TDG Tank Manufacturing / Repair / Modifications

Proven Dual Containment Solutions

for SAGD Sumps and Trenches

est 2002

est 2002

About Us

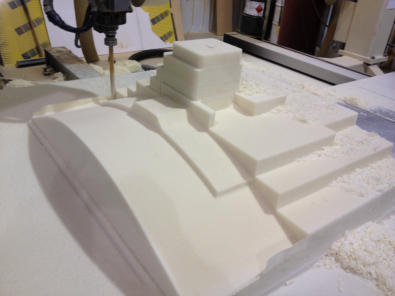

We have been in business since 2002 and along the way have introduced new equipment and production techniques including Vacuum Infusion, RTM Lite and Open Molding. Always striving to be the leader in innovation and technology, we also incorporate the use of a 5 axis CNC to produce accurate masters and molds. Fiberwerx is one of the largest custom fiberglass manufacturers in the region. Our new facility in Kussamo Industrial Park has been designed specifically for fiberglass production and repair. It will not only allow us to have a better working environment for our employees but will also help to ensure better quality control systems for our clientelle.

We are a registered member of ISNetworld and are one of only two facilities in Western Canada registered with Transport

Canada for the manufacturing, modification and repair of fiberglass tdg tanks. We are the exclusive manufacturer for Hamms-

Goldec of Red Deer.

Fiberwerx is also the innovator and holds patents on “Rizor” the worlds most innovative truck bed cover.

See what we can do for you.

© Lorem ipsum dolor sit Nulla in mollit pariatur in, est ut

dolor eu eiusmod lorem 2014

About Us

We have been in business since 2002 and along the way have introduced new equipment and production techniques including Vacuum Infusion, RTM Lite and Open Molding. Always striving to be the leader in innovation and technology, we also incorporate the use of a 5 axis CNC to produce accurate masters and molds. Fiberwerx is one of the largest custom fiberglass manufacturers in the region. Our new facility in Kussamo Industrial Park has been designed specifically for fiberglass production and repair. It will not only allow us to have a better working environment for our employees but will also help to ensure better quality control systems for our clientelle.

est 2002

Custom Manufacturing

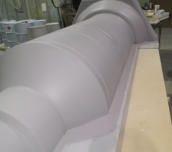

Since 2002 Fiberwerx has been a leader in Custom Manufacturing. As an OEM supplier to Travelaire Canada among others we have produced parts for RV’s, Water slide parks, Dairy Products, Aircraft Parts, Oilfield and Industrial components For more information on any of the follwoing please visit our desktop site.

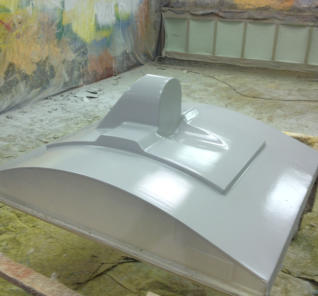

Open Molding

With Open Mold Processing, parts are created by applying gelcoat, resin and fiberglass roving or chopped strand matt to the mold in our specially designed lamination areas. Using the latest in application equipment, quality materials and highly trained staff, open molding offers good quality parts at economical pricing. Fiberglass material and resin are applied either by hand layup (using fabric cut from rolls) or by using a chopper gun , where fiberglass roving is cut into small strands and “sprayed” onto the mold surface with resin and catalyst Typically Open Processing is used for parts were thickness tolerances are not critical. Ideal for larger parts with smaller production runs.

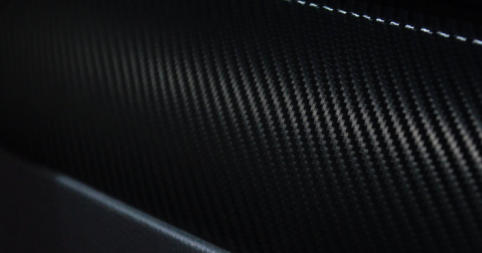

Vacuum Bagging

Vacuum Molds are made with a “wide” flange to accomodate the one of the various bagging methods. The vacuum bag can be a disposable film that is good for one use only, or it can be made with silicone or latex for mulitiple use. While all three are similar in techniques, they are quite different in the actual process. While not quite as accurate with regards to thickness tolerance compared to RTM Lite, it offers benefits over Open Molding. It is more expensive than open molding (fabric cost and bagging costs), but the part consistency is better and there are no VOC’s emitted during the process, thus making a lighter and stronger part.

RTM Lite

Similar to Vacuum Infusion, RTM Lite molds use a wide flange to accommodate vacuum channels and injection ports. Unlike Vacuum Bagging, RTM Lite uses two hard shell molds. By doing this there is better control on part thickness and overall consistency. Like Vacuum Bagging, all harmful emmissions are trapped within the part as it cures. This not only allows for a better cure and a stronger part but is also better for the environment and workplace. RTM Lite is better for suited for smaller parts requiring tighter tolerances. It is also best suited for higher numbers of production runs.

Conceptual Design, Master & Mold Making

We can help you design a 3 dimensional concept of your idea for production as well as being able to create the master in various substrates using our 5 axis CNC mill. Those masters can then be used to create the molds for the various production methods.

Mobile Manufacturing SAGD Sumps and Trenchs

Fiberwerx has developed a “Manufacfured in Place” dual containment system with a monitorable interstitial space compliant with AER regulations. First installed at Devon Energy’s Jackfish One facility, the system has been improved upon and since installed at MEG Energy Chrisitna Lake SAGD and Husky Sunrise. Fiberwerx has also the capability to repair and rebuild frp tanks onsite with the most recent being a 30’tall 14’ diameter tank for Osum energy. All of our fiberglass techs are trained and hold certificates in H2S, Confined Space, Whmis, necessary to allow entry onto most industrial and oilfield sites.

est 2002

© Lorem ipsum dolor sit Nulla in mollit pariatur in, est ut

dolor eu eiusmod lorem 2014

Custom Manufacturing

Since 2002 Fiberwerx has been a leader in Custom Manufacturing. As an OEM supplier to Travelaire Canada among others we have produced parts for RV’s, Water slide parks, Dairy Products, Aircraft Parts, Oilfield and Industrial components For more information on any of the follwoing please visit our desktop site.

Open Molding

With Open Mold Processing, parts are created by applying gelcoat, resin and fiberglass roving or chopped strand matt to the mold in our specially designed lamination areas. Using the latest in application equipment, quality materials and highly trained staff, open molding offers good quality parts at economical pricing. Fiberglass material and resin are applied either by hand layup (using fabric cut from rolls) or by using a chopper gun , where fiberglass roving is cut into small strands and “sprayed” onto the mold surface with resin and catalyst Typically Open Processing is used for parts were thickness tolerances are not critical. Ideal for larger parts with smaller production runs.

Vacuum Bagging

Vacuum Molds are made with a “wide” flange to accomodate the one of the various bagging methods. The vacuum bag can be a disposable film that is good for one use only, or it can be made with silicone or latex for mulitiple use. While all three are similar in techniques, they are quite different in the actual process. While not quite as accurate with regards to thickness tolerance compared to RTM Lite, it offers benefits over Open Molding. It is more expensive than open molding (fabric cost and bagging costs), but the part consistency is better and there are no VOC’s emitted during the process, thus making a lighter and stronger part.

RTM Lite

Similar to Vacuum Infusion, RTM Lite molds use a wide flange to accommodate vacuum channels and injection ports. Unlike Vacuum Bagging, RTM Lite uses two hard shell molds. By doing this there is better control on part thickness and overall consistency. Like Vacuum Bagging, all harmful emmissions are trapped within the part as it cures. This not only allows for a better cure and a stronger part but is also better for the environment and workplace. RTM Lite is better for suited for smaller parts requiring tighter tolerances. It is also best suited for higher numbers of production runs.

Mobile Manufacturing

Fiberwerx has developed a “Manufacfured in Place” dual containment system with a monitorable interstitial space compliant with AER regulations. First installed at Devon Energy’s Jackfish One facility, the system has been improved upon ahd since installed at MEG Energy Chrisitna Lake SAGD and Husky Sunrise. Fiberwerx has also the capability to repair and rebuild frp tanks onsite with the most recent being a 30’ tall 14’ diameter tank for Osum energy. All of our fiberglass techs are trained and hold certificates in H2S, Confined Space, Whmis, necessary to allow entry onto most industrial and oilfield sites.

est 2002

est 2002

Repair Services

Unlike other fiberglass repair facilities, we look at all repairs not only from a Manufcturers standpoint, but in cases of TDG service , also take into consideration the types of conditions that our customers may expose thier item to. All repairs are performed to meet or exceed manufacturers specifications. Ensuring that the proper preparation is done, along with using the proper resins and initiators we can ensure a long lasting repair on most FRP products. Fiberwerx is the ONLY facility in Alberta registered with Transport Canada for the Manufacture, Modification and Repair of fiberglass (FRP) tanks for the transportation of dangerous good. While manufacturing exclusively for Hamms-Goldec of Red Deer, we work with all Canadian Manufacturers (Comptank/Wabash/Tankcon) to ensure compliance with TC requirements.Fiberwerx can perform most repairs / modifications on FRP tanks

including complete tank linings which are certified for tdg service.

FIBERWERX IS ALBERTA’S ONLY TRANSPORT CANADA REGISTERED FACILITY FOR FRP TANKSAll of our qualified fiberglass technicians are given the necessary training and hold certificates in H2S, Confined Space, Whmis, TDG, etc for entry onto most industrial sites. We have two mobile services units allowing us to repair small fractures to rebuildng entire frp strutures onsite. Additionally, Fiberwerx is registered with ISNetworld to enusre rigid safety standards are met.

RV’s,s Boats, Truck hoods, TDG Pipiing, Mechanical shrouds, etc are repaired inhouse to manufacturers specifications using the latest in technologies and materials

Transport Canada Registered Facilty

for Fiberglass TDG

Manufacturing /Repair / Modification

TDG REPAIRS & LINERS

Mobile Service

Misc FRP Repairs

© Lorem ipsum dolor sit Nulla in mollit pariatur in, est ut

dolor eu eiusmod lorem 2014

Repair Services

Unlike other fiberglass repair facilities, we look at all repairs not only from a Manufcturers standpoint, but in cases of TDG service , also take into consideration the types of conditions that our customers may expose thier item to. All repairs are performed to meet or exceed manufacturers specifications. Ensuring that the proper preparation is done, along with using the proper resins and initiators we can ensure a long lasting repair on most FRP products. Fiberwerx is the ONLY facility in Alberta registered with Transport Canada for the Manufacture, Modification and Repair of fiberglass (FRP) tanks for the transportation of dangerous good. While manufacturing exclusively for Hamms-Goldec of Red Deer, we work with all Canadian Manufacturers (Comptank/Wabash/Tankcon) to ensure compliance with TC requirements.

Fiberwerx can perform most repairs / modifications on

FRP tanks including complete tank linings which are

certified for tdg service.

FIBERWERX IS ALBERTA’S ONLY TRANSPORT CANADA REGISTERED FACILITY FOR FRP TANKSAll of our qualified fiberglass technicians are given the necessary training and hold certificates in H2S, Confined Space, Whmis, TDG, etc for entry onto most industrial sites. We have two mobile services units allowing us to repair small fractures to rebuildng entire frp strutures onsite. Additionally, Fiberwerx is registered with ISNetworld to enusre rigid safety standards are met.

RV’s,s Boats, Truck hoods, TDG Pipiing, Mechanical shrouds, etc are repaired inhouse to manufacturers specifications using the latest in technologies and materials

est 2002

TDG REPAIRS

& LINERS

MOBILE

SERVICE

MISC FRP

REPAIRS

est 2002

NEWS

Being a custom fabricator we are often asked to come up with solutions that can’t be done using conventional methods. We have requests to make many different products and when we do so we would like to showcase some of them here. If you read about something and are interested in getting more information about it, email us and we would be happy to point you in the right direction. “ Thank you Scott for building the dragster body for my award winning front engine dragster car that took first place at Motorama 2020. Absolutely perfect fit, you truly do great work” Greg Storey

Posted: Jan 2021

Grey Scorpion Spark Plugs

Sparkplug Crazy Car, Greg Storey, Leduc AB

Greg brought us his sketch for building the fiberglass body for his Spark Plug Car. The plug was carved from eps foam, coated, painted and waxed so that a fiberglass mold could be cast to make the actual body itself. The award winning car has been to many tradeshows and has been featured in “Rods & Customs” magazine

Posted: Jan 2021

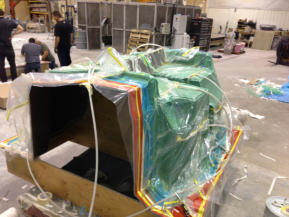

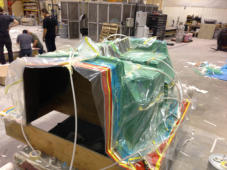

Husky Sunrise Trench & Sump

Dual Containment Remediation, Ft. Mackay AB

Currently in progress, Fiberwerx is fabricating in place and installing our “smart Trench” dual containment system at Husky Sunrise. From the first installation at Jackfish one for Devon Energy, Fiberwerx has developed and perfected our system to meet compliance with AER standards. First installed at J1 in 2012 the system progressed from being premanufactured components to a manufactured in place system that can be done with little or no disruption to regular operations. Installed at MEG Energy’s Christina Lake facility in 2015 both systems are still meeting expectations while systems developed by others have and continue to fail.Shrimp on the Prairies? Strathmore, AB

Joahnn Perslow from SanDiego California approached Fiberwers to build 40 ft long shallow tanks for raising shrimp on a newly constructed facility in Strathmore, Alberta. The tanks varied in length and depth so Fiberwerx constructed the molds in sections that could be changed to accomodate each size without the need to make individual molds. According to PACE, the farms design firm, the farm is capable of producing 1500 kg of shrimp per month.

Posted: Jan 2021

Rocky Mountain Shrimp

© Lorem ipsum dolor sit Nulla in mollit pariatur in, est ut

dolor eu eiusmod lorem 2014

NEWS

Being a custom fabricator we are often asked to come up with solutions that can’t be done using conventional methods. We have requests to make many different products and when we do so we would like to showcase some of them here. If you read about something and are interested in getting more information about it, email us and we would be happy to point you in the right direction. “ Thank you Scott for building the dragster body for my award winning front engine dragster car that took first place at Motorama 2020. Absolutely perfect fit, you truly do great work” Greg Storey

Posted: Jan 2021

Scorpion Performance Spark Plugs

Sparkplug Crazy Car, Greg Storey,

Leduc AB

Greg brought us his sketch for building the fiberglass body for his Spark Plug Car. The plug was carved from eps foam, coated, painted and waxed so that a fiberglass mold could be cast to make the actual body itself. The award winning car has been to many tradeshows and has been featured in “Rods & Customs” magazine

Posted: Jan 2021

Husky Sunrise Trench & Sump

Dual Containment Remediation,

Ft. Mackay AB

Currently in progress, Fiberwerx is fabricating in place and installing our “smart Trench” dual containment system at Husky Sunrise. From the first installation at Jackfish one for Devon Energy, Fiberwerx has developed and perfected our system to meet compliance with AER standards. First installed at J1 in 2012 the system progressed from being premanufactured components to a manufactured in place system that can be done with little or no disruption to regular operations. Installed at MEG Energy’s Christina Lake facility in 2015 both systems are still meeting expectations while systems developed by others have and continue to fail.

Posted: Monday 20th January 2014

Rocky Mountain Shrimp

Shrimp on the Prairies?

Strathmore, AB

Joahnn Perslow from SanDiego California approached Fiberwers to build 40 ft long shallow tanks for raising shrimp on a newly constructed facility in Strathmore, Alberta. The tanks varied in length and depth so Fiberwerx constructed the molds in sections that could be changed to accomodate each size without the need to make individual molds. According to PACE, the farms design firm, the farm is capable of producing 1500 kg of shrimp per month.

est 2002

est 2002

Contact Us

Fiberwerx is conveniently located 20 km west of Red Deer (7 km west of Sylvan Lake) on Hwy 11 in the Kuusamo Industrial Park. Hours of Operation: Mon - Friday 8am - 4:30pm Closed weekends and holidays

Fiberwerx International Inc

214 Kuusamo Close Red Deer County Alberta T4E2J5 Canada t: 403-887-7771 f: 403-887-7737 e: scott@fiberwerx.ca www.fiberwerx.ca

est 2002

© Lorem ipsum dolor sit Nulla in mollit pariatur in, est ut

dolor eu eiusmod lorem 2014

Contact Us

Fiberwerx is conveniently located 20 km west of Red Deer (7 km west of Sylvan Lake) on Hwy 11 in the Kuusamo Industrial Park. Hours of Operation: Mon - Friday 8am - 4:30pm Closed weekends and holidays

Fiberwerx International Inc

214 Kuusamo Close Red Deer County Alberta T4E2J5 Canada t: 403-887-7771 f: 403-887-7737 e: scott@fiberwerx.ca www.fiberwerx.ca

est 2002